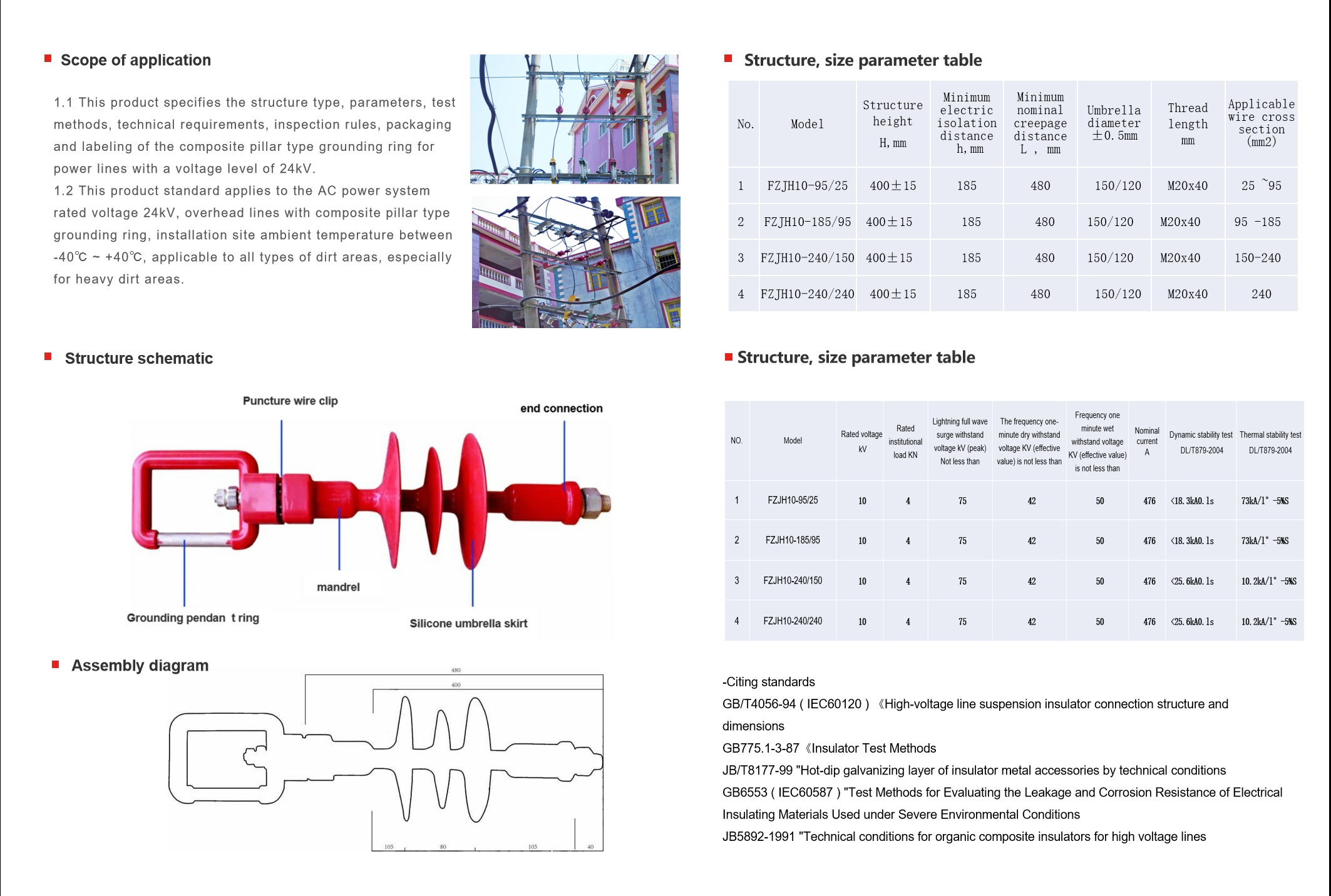

24kV Composite Pillar Grounding Ring

With the progress of urban and rural power grid transformation technology, 24KV distribution network lines are more often using insulated wires that are safer and more reliable in operation. The 24KV composite pillars grounding ring are integrally injected-molded with silicone rubber, which has good hydrophobicity and excellent insulation performance. It uses special fittings and piercing clips, and the fittings produce uniform plastic deformation through synchronous crimping technology, and the interface characteristics are stable.

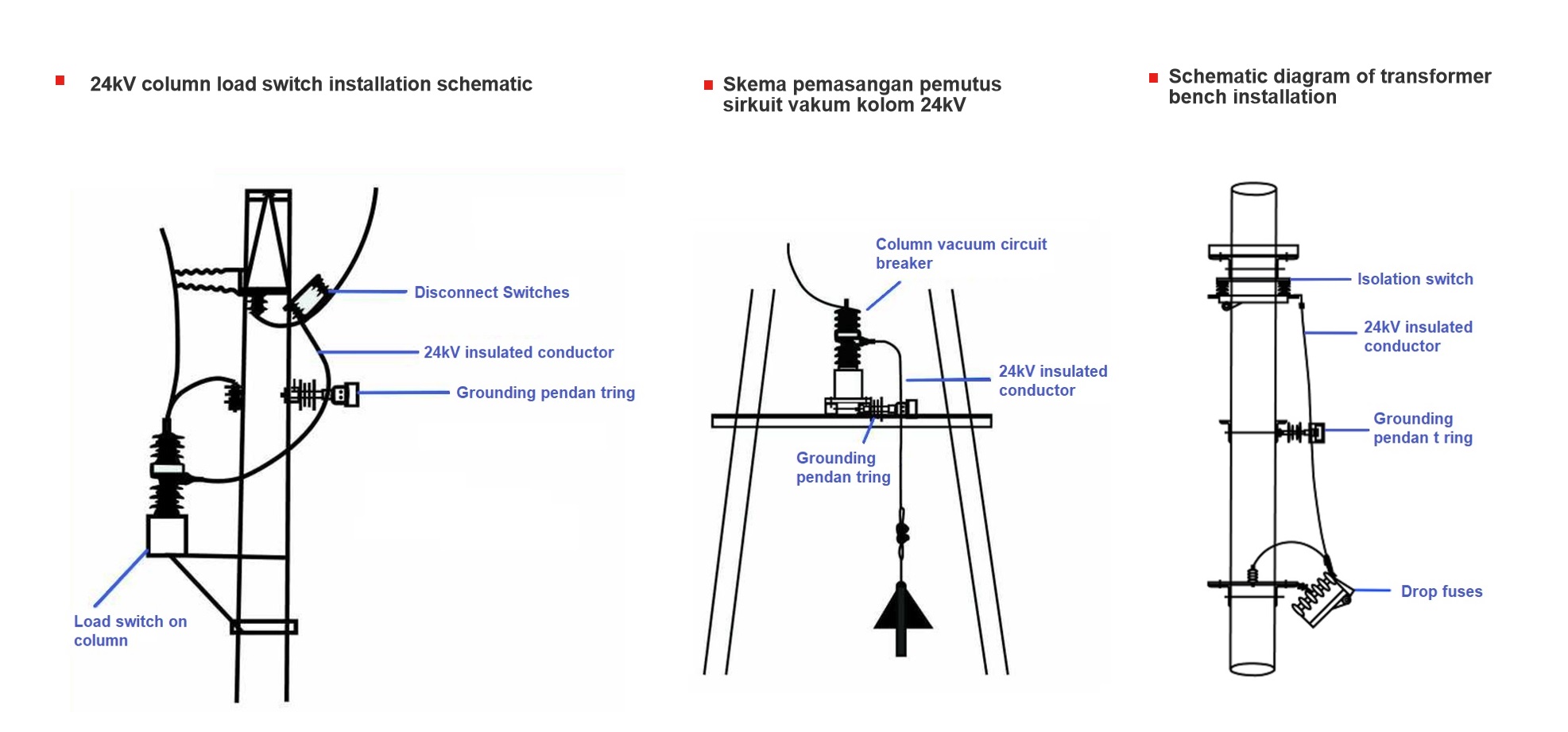

This product adopts pillar type composite insulator combined with piercing wire clip and grounding hanging ring, which can completely solve the risk of distortion and deformation of high voltage fuse caused by hanging and dismantling grounding wire, loss of strands and even dismantling, and will not cause poor contact between grounding hanging ring and high voltage fuse due to the pushing and pulling effect of hanging and dismantling grounding wire on grounding hanging ring during power outage and maintenance.

The product does not need to peel off the wire insulation skin, easy and reliable installation, greatly facilitate the short-circuit grounding wire and personal protection grounding wire hookup during power construction, effectively prevent equipment, lines from sudden incoming calls, eliminate induced voltage, prevent residual charge on the operator's injury.

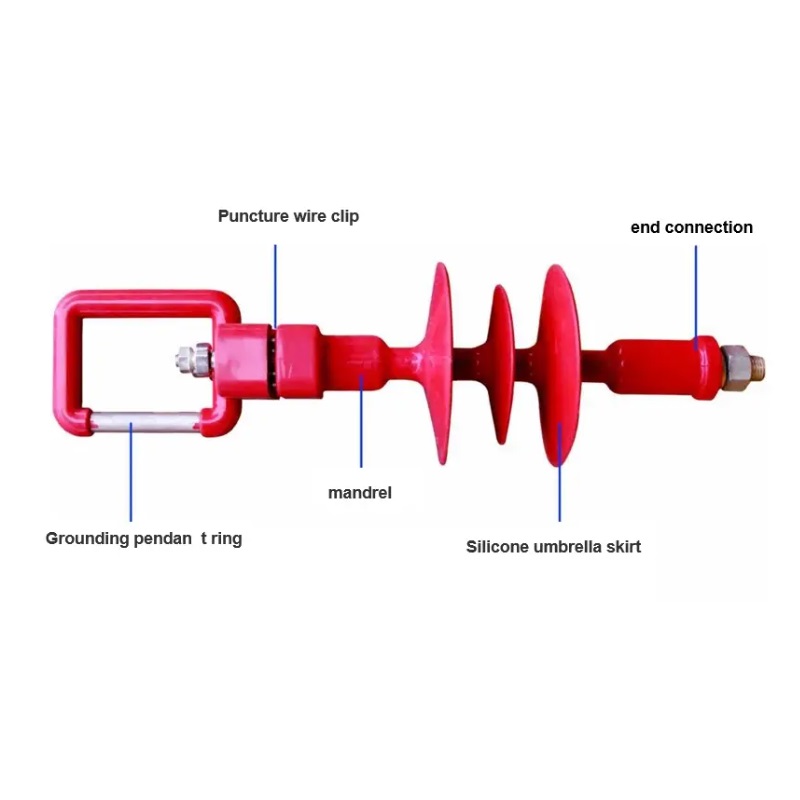

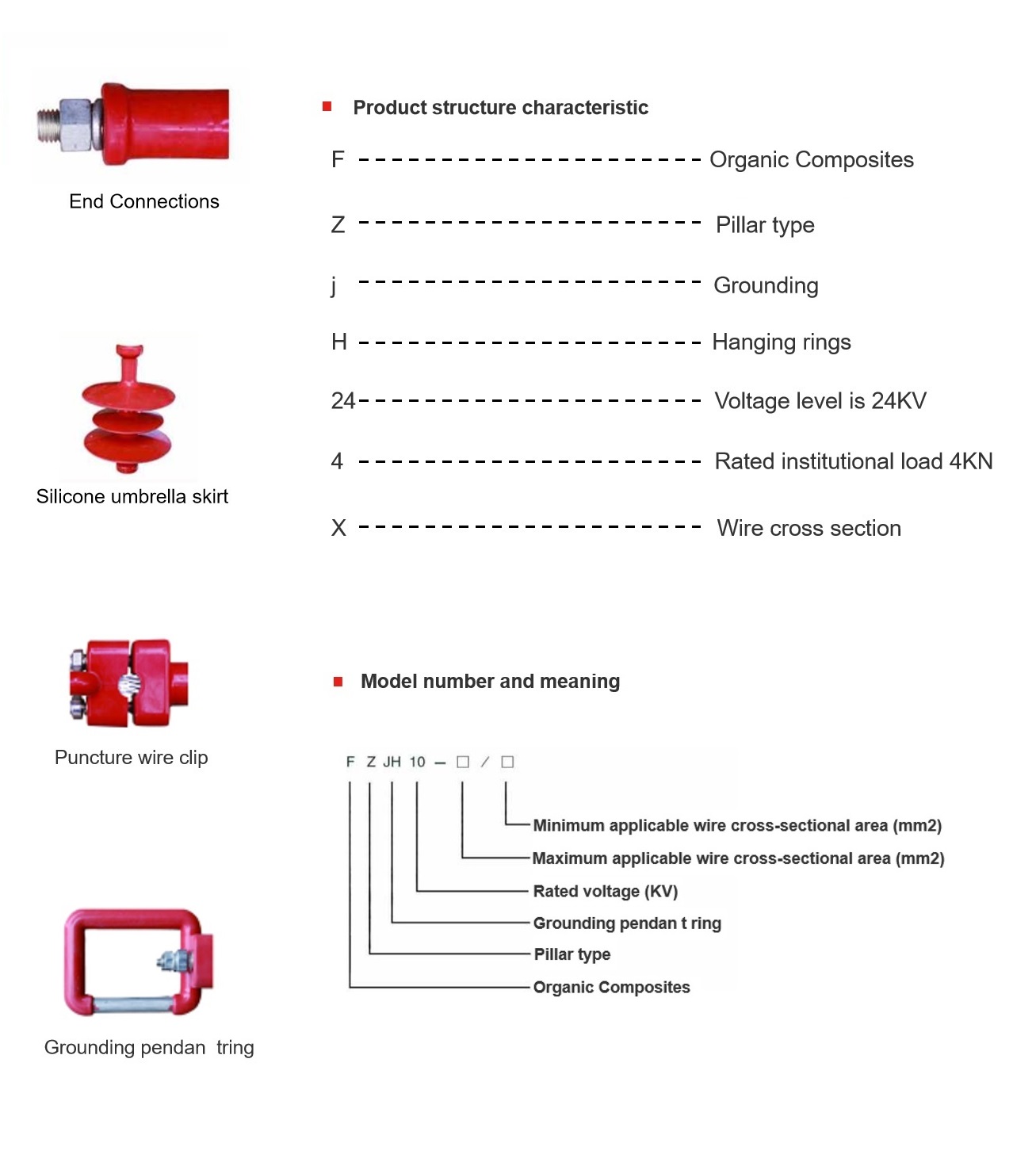

Product structure characteristics

1.End connection: Metal fittings are protected by zinc layer, ultrasonic monitoring, computer-controlled coaxial constant pressure crimping process, the indentation after crimping is as bright as new, the stress dispersion is good, and the quality is stable and reliable.

2. Silicone shed design: The aerodynamically designed silicone rubber shed adopts the integral molding technology of the sheath, and the three-sheath structure of the big and small umbrellas ensures that all creepage distances are effective under any climate and dirty conditions, improving Synthetic insulators are self -cleaning and polluting in the air.

3. Fittings: Made of special steel, the end adopts labyrinth waterproof design, and adopts outsourcing glue technology, which greatly improves the waterproof and anti-seepage performance of the product.

4. Insulation piercing clip: use high conductive piercing blade, the contact resistance is smaller and the current carrying capacity is larger. Anti-oxidation, anti-corrosion stainless steel bolts, easy and smooth installation. It can be selected according to insulated wires of different cross-sections.

5. Grounding ring: made of high-quality aluminum or copper (optional), suitable for copper-aluminum transition. It is mainly used for power inspection or discharge of overhead lines of 24KV and below; it is convenient and reliable for hanging and disconnecting grounding during power outage maintenance.

Products categories

- Online