The main differences between SF6 ring main unit and environmental gas ring main unit are insulation medium, environmental performance, safety and application scenarios.

- Insulation medium: SF6 ring main unit uses sulfur hexafluoride (SF6) gas as insulation medium, while environmentally friendly gas ring main unit adopts new environmentally friendly gases such as perfluoroisobutyronitrile (C4F7N) as insulation medium.SF6 gas has good insulation performance and stability, but it is considered as a strong greenhouse effect gas, which has a great potential of destroying the ecological environment. In contrast, environmentally friendly gases have very low CO2 equivalent emissions and reduce greenhouse gas emissions by more than 99%, providing significant environmental benefits.

- Environmental performance: Although SF6 ring main unit has excellent insulating performance, it has a greater negative impact on the environment due to the use of SF6 gas. Environmental protection gas ring network cabinet by using a new type of environmental protection gas, greatly reducing the impact on the environment, in line with environmental protection requirements, is the future trend of the development of ring network cabinet.

- Safety: Both types of RINGCs are designed with safety in mind. SF6 RINGCs ensure operational safety by adopting measures such as mechanical locking and electrical locking functions. The environmental protection gas ring main unit ensures the sealing and safety of the ring main unit by adopting stainless steel laser-welded completely closed structure design. Meanwhile, all the conductive circuits are wrapped with epoxy resin or silicone rubber, which ensures the high safety of operation and operation.

- Application Scenarios: SF6 ring mains cabinets are widely used for their excellent insulation performance and stability, and are suitable for a variety of complex power needs. Eco-gas enclosures are more suitable for applications that emphasize environmental performance, such as those that need to reduce greenhouse gas emissions, as well as those that implement carbon peaking and carbon neutral strategies.

To summarize, the main difference between SF6 RINGC and EGF RINGC lies in the insulation medium, environmental performance, safety and application scenarios.SF6 RINGCs and EGF RINGCs are common equipments in the electric power industry, and they play an important role in the electric power distribution system. However, with the improvement of environmental protection awareness and the strengthening of environmental protection regulations, the demand for environmentally friendly gas ring main cabinets in the power industry is also gradually increasing. In terms of environmental performance, the SF6 gas used in SF6 ring main cabinets has a high greenhouse effect and global warming potential, while the environmentally friendly gas used in environmentally friendly gas ring main cabinets is environmentally friendly and does not negatively affect the atmosphere, which is in line with modern environmental protection requirements. In terms of market trends, the demand for environmentally friendly gas ring main cabinets in the power industry is gradually increasing with the improvement of environmental protection awareness and the continuous strengthening of environmental protection regulations. More and more electric power companies and projects began to choose the environmental protection gas ring network cabinet, environmental protection gas ring network cabinet will gradually replace the traditional SF6 ring network cabinet, become the mainstream products in the power industry.

Seven Stars Electric Co., Ltd. is a company specializing in the production of environmentally friendly gas cabinets. With a professional R&D team and advanced production equipment, the company is able to provide customers with high-quality environmentally friendly gas ring main cabinet products and solutions. The company is committed to promoting the application of environmentally friendly gas ring network cabinets in the power industry, to meet customer demand for environmentally friendly products, and to help the power industry develop in a more environmentally friendly and sustainable direction.

There are many types of outdoor vacuum circuit breakers, and ZW32 and ZW20 are the most

popular in the market, then what is the difference between them? How to choose?

ZW32 and ZW20 are different in function, methods of using, dimensions;in order to facilitate memory and accurate identification, different model specifications have been written.

ZW32 and ZW20 are the design serial numbers of outdoor vacuum circuit breakers. Their real difference is the difference in appearance and the difference in insulation performance. Different countries or districts have different requirements, the model requirements are also different.

ZW32 series outdoor vacuum circuit breaker shape is pole-mounted type, vacuum arc extinguishing circuit breaker.

ZW20 series outdoor vacuum circuit breaker shape is common box type, is a kind of inflatable circuit breaker with vacuum arc extinguishing, better insulation than ZW32.

Their function is the same in protection of the transformer or wiring line. Both can be divided into manual, motorized or smart types, etc.

The specific difference between the ZW32 and ZW20 is:

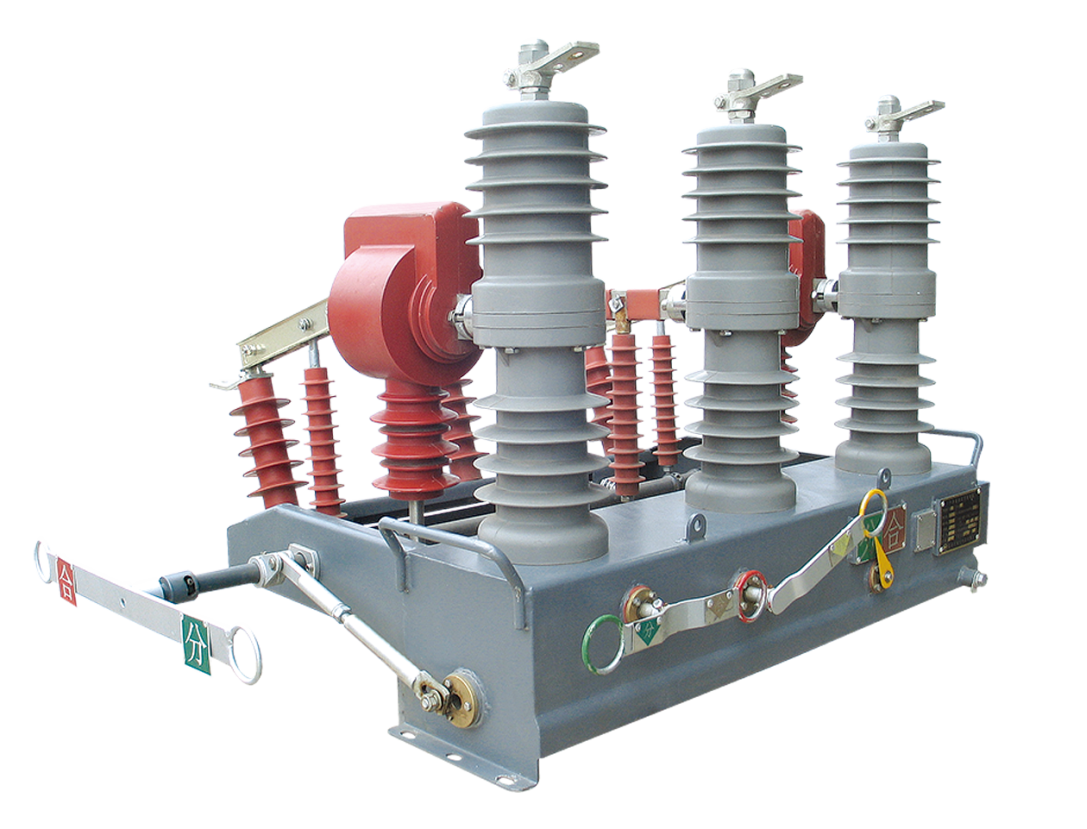

1.ZW32 type outdoor pole-mounted vacuum circuit breaker for rated voltage 12KV, three-phase AC 50Hz outdoor high voltage distribution equipment. It is mainly used to break and close the load current, overload current and short circuit current in the power system. It is suitable for protection and control in the power distribution system of substations and industrial and mining enterprises, and is more suitable for urban and rural power grid construction and transformation and frequent operation places. The ZW32 vacuum circuit breaker is equipped with a spring energy storage operating mechanism, which can be operated manually, motorizedly and remotely. An isolation switch can be installed on the side of the circuit breaker to form an outdoor high-voltage vacuum circuit breaker and an outdoor high-voltage isolation switch combination appliance, which increases the visible isolation fracture and has a reliable interlock operation. According to user requirements, it can be combined with the corresponding controller to form AC high-voltage vacuum automatic recloser, automatic sectioner, self-provided operating power supply, is the ideal equipment to realize the automation of distribution network. High voltage transformer structure can be installed externally or integratedly. ZW32-12G/1250-20, ZW32-12 series poled mounted type outdoor high voltage vacuum circuit breaker is a three-phase AC 50hz, rated voltage 12kv outdoor high voltage switchgear. The circuit breaker is a new miniaturized design, fully enclosed structure, unique arc extinguishing chamber packaging technology, good sealing performance, moisture-proof, anti-condensation, suitable for high temperature and humid areas. ZW32-12G circuit breaker isolation switch combination appliance is composed of ZW32 circuit breaker+ isolation switch.

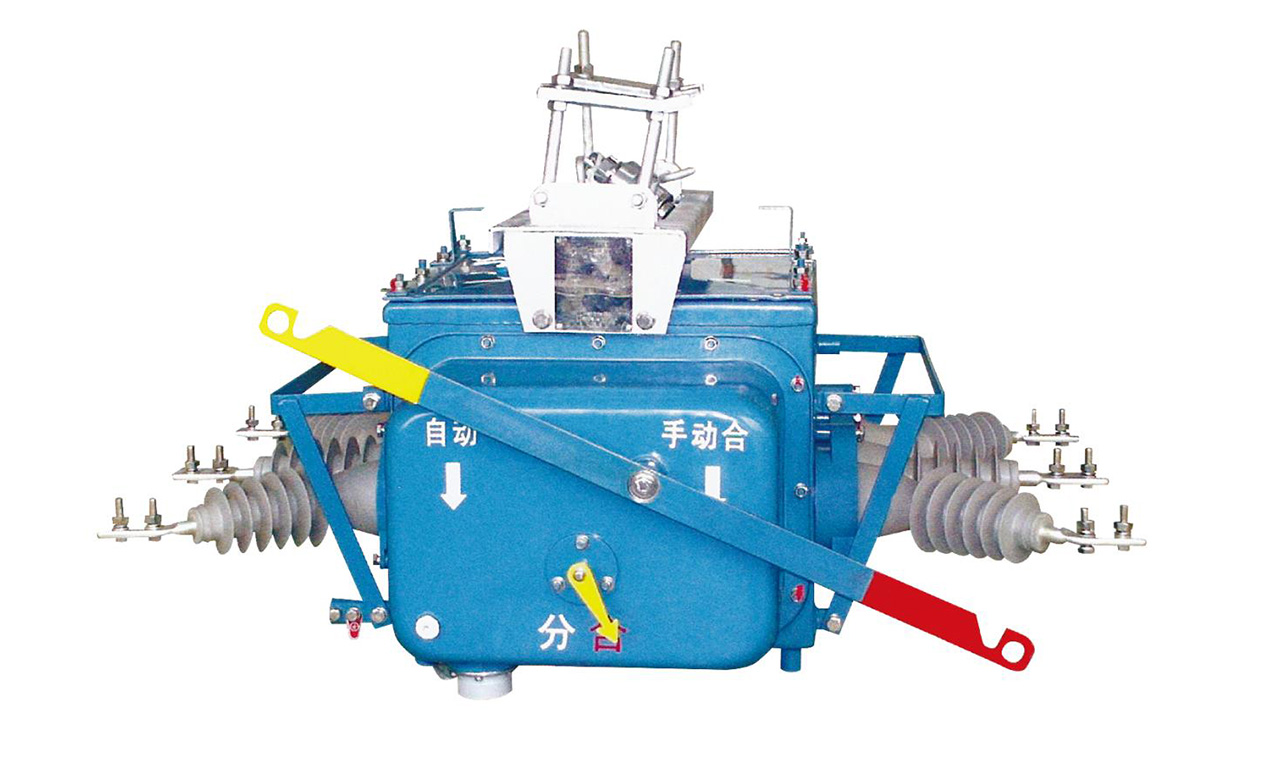

ZW20-12 outdoor AC high voltage demarcation vacuum circuit breaker is a user demarcation switch. It is mainly composed of ZW20-12 vacuum circuit breaker body, fault detection controller and external voltage transformer. The three are electrically connected through aviation socket and outdoor sealed control cable; With fault detection function, protection and control function and communication function, it can detect the zero sequence current and interphase short-circuit fault current in and outside the boundary of the MA level, and realize the automatic removal of single-phase grounding fault and interphase short-circuit fault; Body switch vacuum mode is arc extinguishing and adopts SF6 gas insulation;sealed gas tank with explosion-proof and insulation structure technology, overall sealing performance is excellent, the internal SF6 gas will not leak, and it will not be affected by the external environment. The spring operating mechanism has been miniaturized and optimized in performance design, and the operation reliability is significantly improved compared with the traditional spring mechanism ;The contact between the shaft and sleeve of the main loop is adopted. The contact resistance of the main loop is small and the temperature rise is low.

So the difference between the two is still quite big, both in appearance and performance, there is an essential difference.

Smart type usual operation voltage: 220V

Smart type configuration: FTU, three pcs of current transformers (collectively referred to as: three-phase synthesized zero sequence), voltage transformer commonly known as PT (PT's function is to convert high-voltage 10000V into 220V, and then supply power to FTU). Remote control in opening and closing.

Manual type configuration: two current transformers (AC two-phase protection), can be manually opened and closed.

Shell material: ZW32 is generally made of stainless steel; ZW20 has cold rolled plate spraying, stainless steel.

Both are outdoor high-voltage vacuum circuit breaker, ZW32 cost is relatively higher compared to ZW20. Specific selection is based on environmental conditions, and each utility company’s requirements.

Switches mounted on outdoor poles in 10kV overhead distribution lines are used in suburban and rural distribution networks as mechanical switchgear for breaking, closing and carrying line load currents and fault currents. Conventional pole-mounted circuit breaker (demarcation switch) is mainly organized by switch body + FTU. The first and second fusion complete set of column-mounted circuit breaker is generally organized by switch body + FTU (feeder automation terminal) with sensors.

1、Column switch classification

According to the breaking capacity points:

a. Column disconnecting switch: can not close, open and break the normal load current, there is a clear fracture, used for isolation line maintenance

b. On-column load switch: capable of closing, carrying and breaking normal load current (≤630A), capable of carrying but not breaking fault current switchgear.

c. On-circuit breaker: switchgear capable of closing, carrying and breaking normal load current (≤630A) and fault current (≥20kA).

d. Fuse on the column: to break short-circuit current, protect the line

Arc extinguishing method: vacuum arc extinguishing, SF6 arc extinguishing, oil arc extinguishing (eliminated)

Insulation: air insulation, SF6 gas insulation, composite insulation, oil insulation (eliminated)

Divided according to the controller fitted:

a. Boundary switch: built-in zero sequence transformer, with zero sequence protection function, with load switch or circuit breaker.

b. Voltage type load switch: it can automatically open and close the gate according to the change of line voltage on both sides.

c. Centralized load switch: Cannot actively open and close short-circuit current breakers.

SF6 insulating gas is a colorless, odorless, non-toxic, non-flammable gas, and has excellent electrical insulation and arc extinguishing characteristics, the density is 5 times that of air, and is not easy to leak.

2、 On-column disconnecting switch

Column isolation switch, also known as isolation knife gate, is a kind of control appliances without arc extinguishing device, its main function is to isolate the power supply to ensure the safety of other electrical equipment maintenance, so it is not allowed to operate with load. However, under certain conditions, it is allowed to connect or disconnect small power circuits. It is one of the most frequently used electrical devices among high-voltage switches.

Column isolation switch can be used for line equipment outage maintenance, fault finding, cable testing, reconstruction of the mode of operation, etc., pull open the column isolation switch can make the need for maintenance equipment and other running line isolation, the establishment of a reliable insulation gap, to give the staff can be seen obvious disconnect mark, to ensure that the safety of maintenance or test work. The advantages of column-mounted disconnectors are low cost, simplicity and durability. It is generally used as a demarcation switch for the property rights of the aerial line and the user, and as a demarcation switch for the cable line and the overhead line, and can also be installed on one side or both sides of the line contact load switch to facilitate fault finding, cable testing and maintenance to replace the contact load switch, etc. The disconnecting switch cannot carry rated loads or be used as an isolating switch.

The disconnecting switch cannot be operated with rated load or large load, and cannot divide and close load current and short-circuit current. Generally, during power supply operation, the disconnecting switch is closed first, followed by the circuit breaker or load switch; during power failure operation, the circuit breaker or load switch is disconnected first and then the disconnecting switch.

The disconnecting switch can reliably carry the operating current and short-circuit current, but cannot break the load current. It can open and close the unloaded transformer with an excitation current of not more than 2A and the unloaded line with a capacitance current of not more than 5A. Generally, the dynamic stabilizing current of the disconnecting switch does not exceed 40kA, and attention should be paid to the calibration when selecting the disconnecting switch. The operating life of the disconnectors is about 2000 cycles.

3、Column load switch

Column load switch is a simple arc extinguishing device, can be loaded with the control of electrical appliances to split and close the circuit. It can cut off certain load current and overload current, but cannot cut off short-circuit current, and must be used in series with high-pressure fuse to cut off short-circuit current with the help of fuse.

Load switch is a kind of switching appliance between disconnecting switch and circuit breaker, mainly used for line segmentation and fault isolation.

There are mainly gas-producing load switches, vacuum and SF6 load switches. Gas-producing load switch is the use of solid gas-producing materials composed of slits in the arc under the action of a large number of gases to form a gas blowing arc, because of its simple structure, low cost and was once widely used. Vacuum, SF6 load switch and vacuum, SF6 circuit breaker shape, parameters are similar, the difference is that the load switch is not equipped with protection CT, can not open short-circuit current, but can withstand the short-circuit current, close the short-circuit current, with a long service life, maintenance-free features, mechanical life, rated current opening and closing times of more than 10,000 times, suitable for frequent operation.

Column load switch commonly used in the work is generally used column vacuum load switch. Vacuum load switch adopts vacuum arc extinguishing, SF6 insulation, three-phase common box type, VSP5 electromagnetic or spring operating mechanism, current transformer can be built-in, cable or terminal outlet, can be built-in isolation break, hanging or sitting installation. As shown in the figure below:

In addition to the use of column SF6 load switch liquid quite a few. SF6 load switch with SF6 arc extinguishing, SF6 insulation, three-phase common box type, current transformer can be built-in, cable or terminal outlet, the outside can be equipped with optional isolation device, hanging or sitting type installation.

4、Column circuit breaker

Circuit breaker is a switching device that can close, carry and open the current under normal circuit conditions and can close, carry and open the current under abnormal circuit conditions within a specified time. Circuit breaker can be used to distribute power, infrequently start asynchronous motors, power lines and motors, etc. to implement the protection, when they occur serious overload or short-circuit and under-voltage and other faults can automatically cut off the circuit, its function is equivalent to the fuse-type switches and the combination of over- and under-thermal relays and so on.

Column circuit breaker is a circuit breaker installed and operated on the pole, commonly known as "watchdog", it is a kind of switching equipment that can cut off or connect the line under normal conditions, and switch the faulty line manually or automatically through the operation or the role of relay protection device when the line is short-circuited and faulty. The main difference between circuit breakers and load switches is that circuit breakers can be used to open short-circuit current. Column circuit breaker is mainly used for distribution line interval section casting, control, protection, can open and close short-circuit current.

Column circuit breaker according to the arc extinguishing medium used, can be divided into oil circuit breakers (basic elimination), sulfur hexafluoride (SF6) circuit breakers, vacuum circuit breakers.

The original distribution network project using sulfur hexafluoride (SF6) circuit breakers and vacuum circuit breakers are more, and now the distribution lines in the circuit breaker is mainly used in outdoor AC high-voltage intelligent vacuum circuit breakers, intelligent vacuum circuit breakers with fault detection function, protection and control functions and communication functions. Generally installed in the 10kV overhead line duty demarcation point, can realize automatic resection, single-phase grounding and automatic isolation of short-circuit faults, is the ideal product for distribution line reconstruction and distribution network automation construction.

Intelligent vacuum circuit breaker can be operated manually, electrically, by remote control and by remote host. The circuit breaker consists of three parts: body, operating mechanism and controller (isolation switch can be built-in). The circuit breaker can be equipped with CT (protection current transformer), ZCT (zero sequence current transformer), u (voltage transformer) as the detector of the controller according to the need.

Vacuum circuit breaker according to the absolute insulation material has SF6 insulated vacuum circuit breaker and air insulated vacuum circuit breaker. SF6 insulated vacuum circuit breaker adopts vacuum interrupter, SF6 insulation, three-phase common box type, adopts spring operation mechanism, the current transformer can be built-in, cable or terminal out of the line, the external optional isolation device, hanging or sitting type installation. Air-insulated vacuum circuit breaker adopts vacuum arc extinguishing, air insulation, three-phase solid-sealed pole-column type, adopts spring or permanent magnet operating mechanism, current transformer can be built-in, cable or terminal outlet, external optional isolation device, sitting type installation.

5、Drop-in fuse

Falling fuse commonly known as Link, is a 10kV distribution line branch line and distribution transformer most commonly used a short circuit protection switch. It has economic, easy to operate, adapt to the outdoor environment and other characteristics, is widely used in 10kV distribution lines and distribution transformers as a primary side of the protection and equipment casting, cutting operation.

Drop fuse installed in 10kV distribution line branch line, can reduce the scope of power outage, because it has a high-voltage drop fuse obvious disconnection point, with the function of the isolation switch, to the maintenance section of the line and equipment to create a safe operating environment, increase the safety of maintenance personnel. Installed on the distribution transformer, it can be used as the main protection of the distribution transformer, so it has been popularized in 10kV distribution lines and distribution transformers.

The fuse can be installed on the power side of the load switch or on the powered side of the load switch. When it is not necessary to frequently drop the fuse, it is desirable to adopt the former arrangement in order to utilize the function of the load switch as a disconnecting switch, and use it to isolate the voltage added to the current-limiting fuse.

The composition of the falling fuse mainly consists of insulator , lower support seat, lower movable contact, lower static contact, mounting plate, upper static contact, duckbill, upper movable contact, fuse tube and so on.

6. Differences in column switches

The main differences are as follows:

The disconnecting switch has no arc extinguishing device, so it is only suitable for cutting off the current without load, and it can not cut off the load current and short-circuit current, so the disconnecting switch appliance can only be operated safely under the condition of circuit safety disconnection, and it is forbidden to operate with a load, so as not to cause a safety accident.

Load switch because of the arc extinguishing device, with a certain arc extinguishing ability, but not as strong as the circuit breaker arc extinguishing ability, he can split the normal operating current, short circuit, he can only silently withstand the short-circuit current, if this time manually or electrically operated tripping may be exploded, so the load switch is generally used with the current-limiting fuse (load switch + fuse is not the standard configuration, but also can not be used with a fuse) In case of overload or short-circuit the circuit is broken by a fuse. In order to save cost, load switch + fuse can be used instead of circuit breaker.

The circuit breaker has a strong arc extinguishing ability, and it can tap the normal working current as well as the fault current. The protection function of the circuit breaker is realized by the relay protection device. High-voltage circuit breakers do not have the devices of low-voltage circuit breakers such as thermal release, magnetic release, under-voltage release, etc. Whether there is a fault in the line is judged by the relay protection device, and the circuit breaker only performs breaking according to the instruction of the relay protection. Load switches and disconnecting knives are also not required to give commands to them when the line is faulted because they cannot break the fault current. The circuit breaker is a switch with high arc extinguishing capability and must be used in conjunction with the relay protection device.

By We can conclude as follows:

Disconnecting switch - can only open and connect the system no-load current, and as the main wiring system obvious disconnection point, in the maintenance process as the system obvious disconnection point. Commonly used models: GW9, HGW9, GW4, GW5, etc.

Load switch - can open and close the system normal load current, but cannot break the system fault current. Commonly used models: FZW32

Circuit breaker--Can open and close the normal load current of the system, but also can open and close the fault and short-circuit current of the system. Commonly used models: ZW32, ZW20, ZW7, ZW8, LW3, etc.